- ZPG

- High frequency vibration dewatering sieve

- Heavy-duty belt filter press

- Chain Feeder

- Ceramic Filter

- Inclined Plate Thickener

- The Flotation Machine

- Scraper Conveyor

- XK type slurry preparation device

Contacts:Mr.Fei

Tel:0510-83771115

Mobile:13328107097

Mail:fxc7070@sina.com

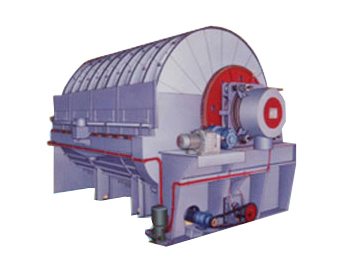

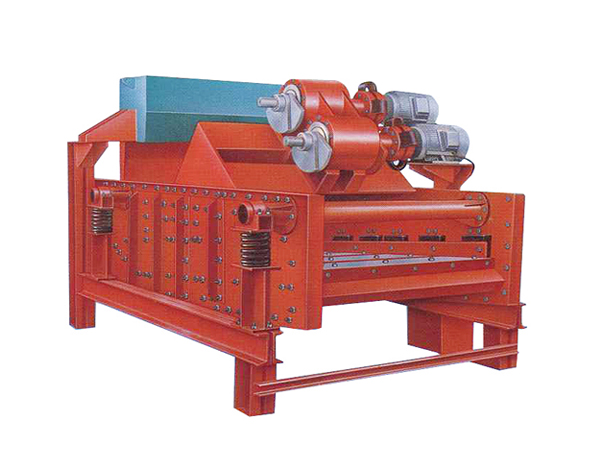

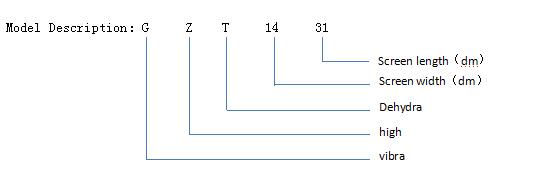

GZT series of high frequency vibration dehydration sieve

Source:http://www.wxhdksjx.com Time:2017/5/11 13:58:55

GZT series of high frequency vibration dehydration sieve

Overview

High-frequency vibration dehydration referred to as sieve high-frequency sieve, through the exciting force to change the water surface of the slurry of water, pulp through the screen to become sieve, and fine materials are screened to form a filter layer, the material by the vibration force forward discharge. High-frequency screen is mainly used for mineral processing industry tailings dehydration, coal preparation plant of coal dehydration, washed quartz sand dehydration and potassium feldspar dehydration.

working principle

The screen machine uses self-synchronous liquid lubrication vibrator, under the action of exciting force, the screen for high frequency and high vibration intensity reciprocating motion. According to the different role, along the full length of the screen is divided into pre-dehydration area, filter layer forming area and extrusion dehydration area.

(1), pre-dehydration zone: in the screen machine vibration force and logistics centrifugal force, into the area close to the surface of the fluid movement, near the surface of the screen and the water is less than the sieve fine particles were sieve cutting and screening, And coarse particles are separated in the screen surface, and along the screen surface down, can remove most of the water, for the formation of filter layer to prepare.

(2), filter layer formation area: due to the special structure of the screen surface, the material in the arc and straight section of the screen surface transition occurs when the speed of the sudden roll, in the appropriate vibration parameters, coarse particles quickly settling close to the screen surface , Forming a filter layer, which in the extrusion zone to play a role in blocking fine particles through the screen.

(3), extrusion dehydration zone: with the continuous feeding and sieve machine vibration conveyor, the material was forced into the extrusion zone. After high-frequency vibration and squeezing force of the double, the material to complete the dehydration from the export excluded.

Main technical characteristics

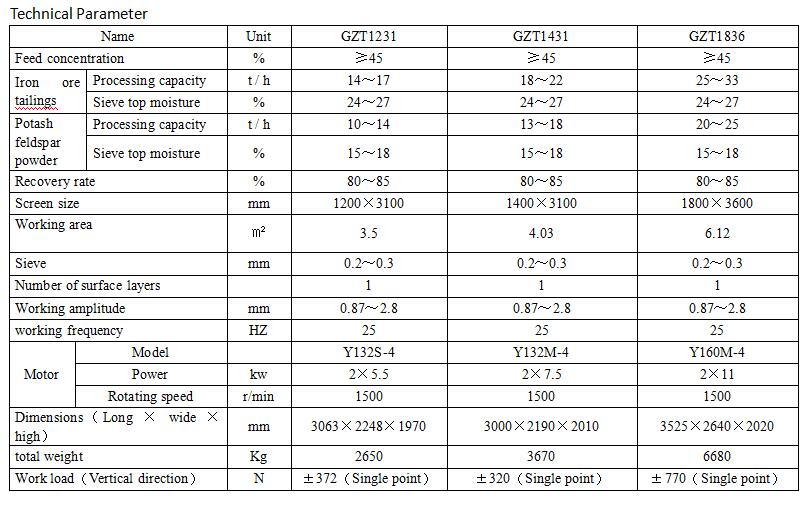

(1), high vibration parameters: operating frequency 25HZ, vibration intensity 7g.

(2), the use of self-synchronous liquid lubrication vibrator excitation, the screen frame with special noise reduction materials and high-strength bolts to ensure that the sieve machine work is reliable and low noise, the machine noise 85dB (A) The screen machine is reduced by about 15 dB (A).

(3), the feed section set the curved screen surface, improve dehydration efficiency.

(4), the screen surface with a unique negative angle design, the material after the climbing extrusion dehydration, lower moisture content.

(5), with a feed box, to ensure that the material evenly into the sieve surface.

(6), relying on sieve filter layer to remove fine particles and extrusion dehydration.

(7), amplitude adjustment range (0.87 ~ 2.8mm), to adapt to a wide range of materials.

(8), sieve plate made of polyurethane wear-resistant materials, improve service life.

- Previous Article:没有了!

- Next Article:没有了!

-

How should Hengda mining machinery cope with new opportunities?

Hengdaminingmachineryshouldbehowtodealwithth...

MORE -

Hengda mine manufacturers tell you the importance of the valve

Hengdaminemanufacturerstellyoutheimportanceo...

MORE -

Anhui ZPG50-10 disc vacuum filter delivered smoothly

AnhuiZPG50-10discvacuumfilterdeliveredsmoothly...

MORE -

Combined dewatering of lead and zinc tailings thickener and disc vacuum filter

Combineddewateringofleadandzinctailingsthickeneranddiscv...

MORE -

Chengde Tianbao Group ZPG120-10 disk vacuum filter delivery

ChengdeTianbaoGroupZPG120-10diskvacuumfilterdelivery...

MORE -

承德ZPG120-10盘式真空过滤机顺利发货

承德ZPG120-10盘式真空过滤机顺利发货 ...

MORE