- ZPG

- High frequency vibration dewatering sieve

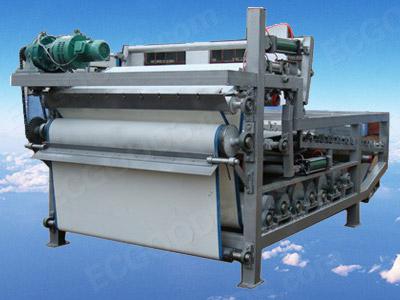

- Heavy-duty belt filter press

- Chain Feeder

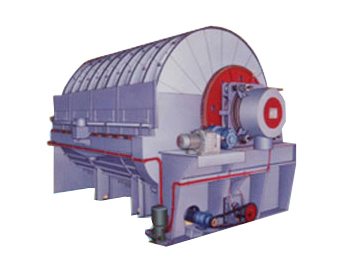

- Ceramic Filter

- Inclined Plate Thickener

- The Flotation Machine

- Scraper Conveyor

- XK type slurry preparation device

Contacts:Mr.Fei

Tel:0510-83771115

Mobile:13328107097

Mail:fxc7070@sina.com

Heavy-duty belt filter press

Source:http://www.wxhdksjx.com Time:2017/5/12 10:19:09

Summary

The DYZ heavy belt filter press is based on the common belt filter press. The gravity dewatering section is lengthened, the gravity dewatering section is longer, and the sludge concentration effect is better. The utility model has all the characteristics of a universal belt filter press, and is more efficient and larger than a universal belt filter press. Can be widely used in various sludge dewatering treatment, such as paper making, municipal sewage, chemical, tailings, sand making, sand washing, construction sludge and so on.

Characteristic:

(1) the unique overall layout and configuration, compact and reasonable structure, multi-stage pressure filtration, effectively reduce the water content of mud cake.

(2) the main frame adopts high strength square steel tube, the surface is antiseptic, acid and alkali resistant and corrosion resistant.

(3) the extruded roller, guide roller, transmission roller and idler roller are welded by high strength seamless steel tube. The outer layer is coated with wear-resistant and acid resisting alkali and high quality rubber.

(4) the big screen roller adopts new type of steel structure and, through the spindle, high strength; surface water distribution, water filtering performance is good, not anti permeability.

(5) each screen adopts an independent bias adjustment system, electronic induction, sensitive and reliable. The utility model also has the functions of deflection, failure, alarm and stop function, and the effective protection filter screen is not damaged.

(6) the static mixer is used in conjunction with the spiral coagulation machine to make the reaction of the reagent and slurry more fully and save the dosage of the medicament.

(7) the main engine adopts frequency conversion speed regulation to control the running speed of the main filter belt, so that the equipment can reach the ideal state.

Working principle

After precipitation concentrated sludge and flocculant in the static mixer and spiral coagulation machine (dynamic mixer) in fully mixed reaction, small solid particles in the sludge into larger poly flocculent masses, and separation of free water, flocculated sludge is transported to the concentrated gravity dewatering filter belt, are separated in the free the water under the action of gravity, the formation of the flow state of the sludge, and then sandwiched between the upper and lower two belts with wedge after preloading, the low pressure zone and the high pressure area from the extrusion pressure, the effect of shear stress, further squeezing mud, mud and water in order to achieve the maximum degree of separation, the final form of filter the cake to discharge.

1. Pretreatment dehydration

The original sewage after treatment, biochemical physicochemical process, after precipitation and concentration, become a part of the water liquid discharge, sewage sludge formed a higher concentration of the original, in order to achieve the best working condition of belt type filter press.

2. Gravity dewatering zone

Gravity dewatering zone can also be said to be highly concentrated area, after pretreatment of the sludge after sludge pump to the static mixer and mixed flocculant, further mixing coagulation machine in a spiral, the sludge and flocculant fully reaction, flocculation, and then evenly into the filter belt, which began with gravity dehydration, filter material with the move, free water under gravity through the filter belt into the gutter.

3, wedge zone pre pressure dewatering

The flow of the sludge gravity dehydration after almost completely lost, with the filter belt is moving forward on the filter belt spacing decreases gradually, the material began to be slight pressure, and with the filter with the operating pressure gradually increases, the wedge area is the role of extended gravity dehydration time, extrusion stability increased floc, ready to enter pressure zone.

4, roll dehydration

The material from the wedge into the pressure zone, the material in this area is squeezed, running along the direction of the filter belt pressure increases with the extrusion roller diameter, material by extrusion shrinkage, clearance of free water in material is extruded, the basic form filter cake, high pressure area and continue to move forward to the tail, after high pressure zone the water content of the filter cake can be reduced to the lowest.

5, filter cake discharge

The material after dehydration treatment above each stage after the formation of the filter cake discharged by scraping mud scraping plate, upper and lower filter belt separately, after high-pressure washing water to remove the filter net trace material between the holes, continue to enter the next cycle of dehydration.

- Previous Article:没有了!

- Next Article:没有了!

-

How should Hengda mining machinery cope with new opportunities?

Hengdaminingmachineryshouldbehowtodealwithth...

MORE -

Hengda mine manufacturers tell you the importance of the valve

Hengdaminemanufacturerstellyoutheimportanceo...

MORE -

Anhui ZPG50-10 disc vacuum filter delivered smoothly

AnhuiZPG50-10discvacuumfilterdeliveredsmoothly...

MORE -

Combined dewatering of lead and zinc tailings thickener and disc vacuum filter

Combineddewateringofleadandzinctailingsthickeneranddiscv...

MORE -

Chengde Tianbao Group ZPG120-10 disk vacuum filter delivery

ChengdeTianbaoGroupZPG120-10diskvacuumfilterdelivery...

MORE -

承德ZPG120-10盘式真空过滤机顺利发货

承德ZPG120-10盘式真空过滤机顺利发货 ...

MORE