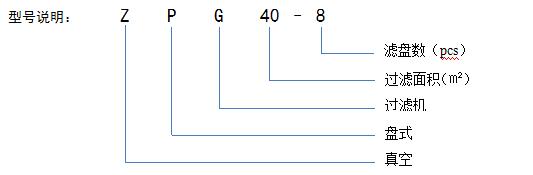

- ZPG

- High frequency vibration dewatering sieve

- Heavy-duty belt filter press

- Chain Feeder

- Ceramic Filter

- Inclined Plate Thickener

- The Flotation Machine

- Scraper Conveyor

- XK type slurry preparation device

Contacts:Mr.Fei

Tel:0510-83771115

Mobile:13328107097

Mail:fxc7070@sina.com

ZPG disk vacuum filter

Source:http://www.wxhdksjx.com Time:2017/5/16 10:18:33

Applicable to metallurgical ore dressing industry

Summary

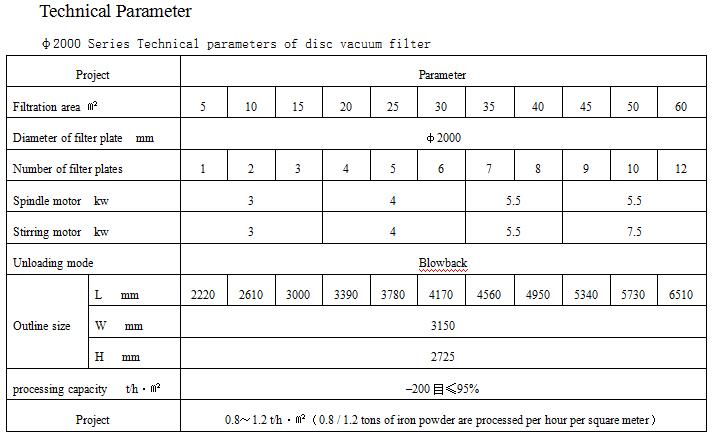

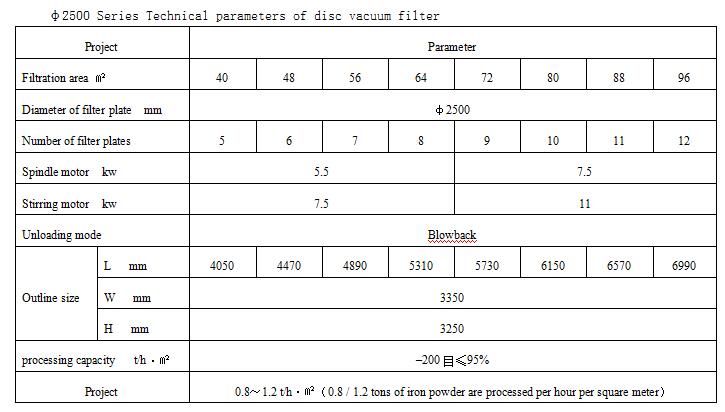

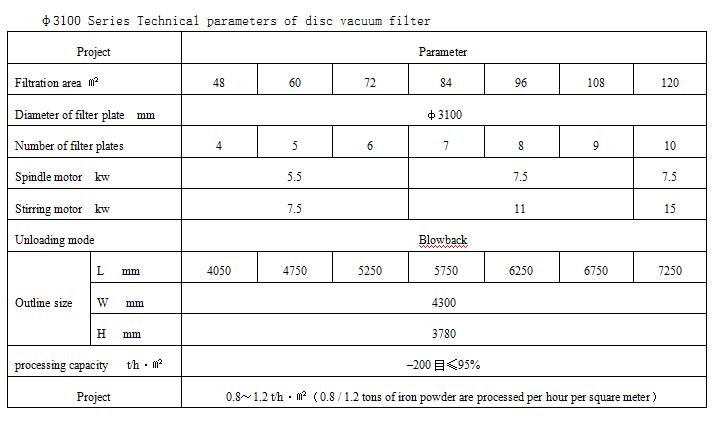

ZPG (GPT/PGT) disk vacuum filter is a kind of equipment which uses vacuum as filter power to separate the slurry from the solid and liquid.

This machine is a new type of disc vacuum filter specially designed for dewatering of iron concentrates and non-ferrous metal ores.

ZPG disc vacuum filter fully absorbed the advanced technology of similar products at home and abroad, combined with the domestic user feedback, continuous optimization and improvement, the product is durable and reasonable design. For metal ore than the major, easy to precipitate, easy to wear equipment and other characteristics, the spindle stepless speed regulation, automatic transmission, strong stirring blowback unloading, automatic lubrication, reliable sealing, stirring composite ceramic filtrate tube, filter automatic cleaning techniques. With the most advanced automatic discharge device, -SX series automatic water discharge device, making it a good performance, reliable use of dehydration equipment.

Filter fan and filter bag:

Our company aims at the mineral characteristics of the metal ore dressing industry. After many years of continuous optimization and improvement, we have developed a series of special filter fans to meet the requirements of different metal mines.

1, each disk filter fan a sector plate 20 18 degree angle, compared each disc into 12 fan-shaped plates, each sector plate in the suction zone can advance 12 degrees of suction, can extend 12 degrees of dewatering and drying in the drying zone, it means to have a higher yield, lower. Water.

2 、 filter fan made of high strength polypropylene, high strength, reasonable structure design, strong and durable.

3, we insist on the use of new material production, never add renewable material, the service life is 2~3 times the market ordinary filter fan.

4. The surface is smooth and smooth, the distribution of the filtrate channel is uniform, the opening rate is reasonable, and the liquid and gas are unimpeded.

5. The fan handle is die-casting at once, with high strength. The caliber of the suction hole is increased, and the filtrate water can flow rapidly, and no water is accumulated in the filter fan.

6, for corrosion and special requirements, can be equipped with stainless steel bolts.

7. The filter cloth is made of German fabric, and the multi-layer fiber structure and supporting base fabric make it extremely compact and stable. The utility model has the advantages of smooth surface, uniform pore, easy blockage, and longer service life compared with domestic filter cloth.

Two spindle and filtrate pipe:

1. The spindle intermediate shaft is made of high quality steel tube. The overall strength is high. Compared with the steel plate roll welding process, the torsion resistance is stronger and the service life is more than 10 years.

2. The filter pipe is made of seamless ceramic composite pipe. The interface between the filter fan and the filter pipe is welded and molded by a special mold to ensure the accuracy after welding. The pore size of the filtrate pipe is large, which is beneficial to the rapid passing of filtrate water, and the residual liquid in the filter fan is prevented from affecting the water content of the mineral powder.

3, the main and from the ends of the allocation of head, using a special structure, in the air balance zone, can quickly remove the filtrate pipe and filter fan residual fluid,

It is forbidden to blow out the residual liquid in the process of anti blowing and discharging to influence the moisture content of the mineral powder.

4. The outside of the filter fan disc is compressed and fixed by segmented channel steel (or high strength engineering plastic), so it is convenient to install and disassemble. It is easy to change the filter cloth and fan the later stage.

Three, stir:

1, in view of the particularity of metal ore powder, combined with the feedback suggestions made by users, the mixing and sealing system adapted to different materials has been designed. After user practice, compared to the market, the conventional sealing method is not easy to leak, durable advantages.

Characteristic:

A) magnetic seal - prevents the iron powder from entering the flexible sealing area of the mixing end shaft

B) VD type sealing ring

C) water seal

D) skeleton oil seal

E) combined packing

F) chrome plating on the shaft surface

2, mixing device for frequency control, blade using 16Mn steel forging forming, compared to ordinary materials, more wear-resistant, longer service life. The leaves are arranged in the cross arrangement of "ten" words, and the leaves of the leaves are curved, so the stirring is more complete, the cake is uniformly distributed, and the cake shedding rate can reach more than 95%.

Four, trough:

1. The tank is welded by high quality steel. The bottom of the tank is lined with 16Mn steel plate (or corundum ceramic), which solves the problem that the bottom of the tank body is not wearable and easy to be damaged.

2, for different materials, you can choose different materials and new techniques to make the tank. Example: carbon steel, Q235, stainless steel, 304L/316L, macromolecule board lining, multi layer epoxy anticorrosive coating, etc..

Five 、 control panel and friction plate:

The boron carbide cast iron with high wear resistance is used to form phosphorus boron carbide. With grease lubrication, move among force and soft, good sealing property, prolonging the service life of 2 to 3 times.

Six 、 lubrication and cleaning:

1, using dry oil pump multi-point centralized automatic lubrication system, reduce maintenance, ensure the reliable operation of equipment.

2 、 filter cloth adopts automatic washing device, no need to stop production, work while cleaning, keep good dehydration effect.

Seven, electronic control:

The main engine adopts frequency conversion speed regulation, which can be adjusted according to the concentration and flow of the material to ensure the equipment to achieve the best working condition.

- Previous Article:Cement used disk vacuum filter

- Next Article:Description of ZPG type vacuum filter (tailings)

-

How should Hengda mining machinery cope with new opportunities?

Hengdaminingmachineryshouldbehowtodealwithth...

MORE -

Hengda mine manufacturers tell you the importance of the valve

Hengdaminemanufacturerstellyoutheimportanceo...

MORE -

Anhui ZPG50-10 disc vacuum filter delivered smoothly

AnhuiZPG50-10discvacuumfilterdeliveredsmoothly...

MORE -

Combined dewatering of lead and zinc tailings thickener and disc vacuum filter

Combineddewateringofleadandzinctailingsthickeneranddiscv...

MORE -

Chengde Tianbao Group ZPG120-10 disk vacuum filter delivery

ChengdeTianbaoGroupZPG120-10diskvacuumfilterdelivery...

MORE -

承德ZPG120-10盘式真空过滤机顺利发货

承德ZPG120-10盘式真空过滤机顺利发货 ...

MORE