- ZPG

- High frequency vibration dewatering sieve

- Heavy-duty belt filter press

- Chain Feeder

- Ceramic Filter

- Inclined Plate Thickener

- The Flotation Machine

- Scraper Conveyor

- XK type slurry preparation device

Contacts:Mr.Fei

Tel:0510-83771115

Mobile:13328107097

Mail:fxc7070@sina.com

Ceramic Filter

Source:http://www.wxhdksjx.com Time:2017/5/11 13:57:23

Ceramic filter

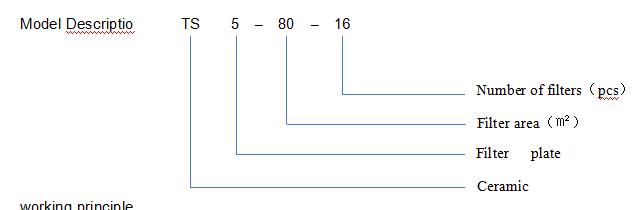

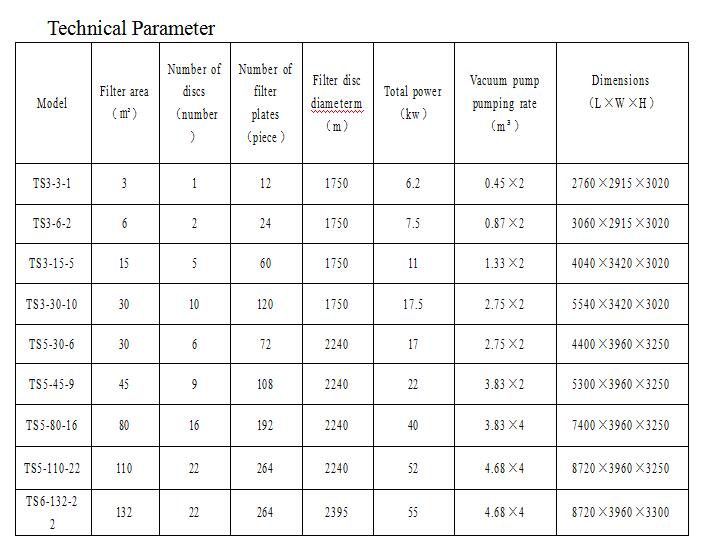

TS series of ceramic filter

Overview

TS ceramic filter series products are microporous ceramic plate, automatic control, ultrasonic cleaning system, efficient soft drinks separation system, and other high-tech in one of the new products. It is widely used in solid-liquid separation of nonferrous metals, mining, chemical industry, coal, metallurgy, environmental protection, power generation, coal ash treatment, sewage treatment and so on.

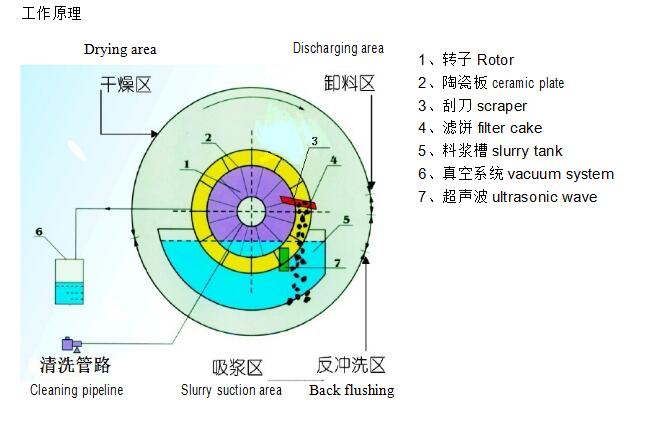

Rotor (ceramic plate) running a week, the work process is divided into four areas: pulp (material) area, drying area, discharge area, cleaning area, repeated cycle.

⑴ filter cake formation (suction area)

At the beginning of the work, the composite microporous ceramic plate immersed in the slurry tank under vacuum, the surface of the formation of a thick layer of particle accumulation, the filtrate through the ceramic plate filter into the distribution valve to the vacuum barrel.

⑵ filter cake dry (drying area)

The filter cake continues to dry under vacuum.

⑶ filter cake stripping (discharge area)

In the scraper device under the action of discharge.

⑷ backwash (rinse area)

The use of compressed air and ceramic filter itself, the filtrate or tap water (such as industrial water can also be used after precipitation), through the backwash pipe through the pressure adjustment by the distribution valve into the ceramic plate cavity, from the inside and outside cleaning ceramic plate micro Hole, while the residual ceramic particles in the surface of the residual mineral flushing down to achieve the purpose of cleaning.

⑸ joint cleaning (chemical cleaning and ultrasonic cleaning)

After a certain period of time after the ceramic plate (usually 7 to 8 hours), the joint cleaning system is enabled, through ultrasonic, chemical cleaning and backwashing interaction to achieve the best cleaning effect. Through the joint cleaning can make the ceramic plate to further clear the pores, so that the subsequent filtration can ensure high efficiency.

Technical characteristics

1, high vacuum, low water filter cake.

2, the filtrate water is clear, can be used repeatedly to reduce emissions.

3, compared with the filter cloth vacuum filter, the whole low power consumption, saving about 80% power consumption, reduce operating costs.

4, the use of touch screen combined with PLC control, to achieve the machine's automatic control.

5, the spindle, mixing reducer are used frequency control, easy to operate, reliable operation.

6, the use of ultrasonic combined with chemical cleaning agent combined cleaning ceramic plate, a strong guarantee for efficient use of ceramic plates.

7, automatic acid, reduce labor intensity and risk

8, for different materials, can be used in different mixing methods, such as: mechanical, pneumatic, modular, to achieve the best mixing effect.

9, the use of efficient filtrate discharge system, excluding the filtrate pump and liquid level detector long-term operation of the unreliable.

- Previous Article:没有了!

- Next Article:没有了!

-

How should Hengda mining machinery cope with new opportunities?

Hengdaminingmachineryshouldbehowtodealwithth...

MORE -

Hengda mine manufacturers tell you the importance of the valve

Hengdaminemanufacturerstellyoutheimportanceo...

MORE -

Anhui ZPG50-10 disc vacuum filter delivered smoothly

AnhuiZPG50-10discvacuumfilterdeliveredsmoothly...

MORE -

Combined dewatering of lead and zinc tailings thickener and disc vacuum filter

Combineddewateringofleadandzinctailingsthickeneranddiscv...

MORE -

Chengde Tianbao Group ZPG120-10 disk vacuum filter delivery

ChengdeTianbaoGroupZPG120-10diskvacuumfilterdelivery...

MORE -

承德ZPG120-10盘式真空过滤机顺利发货

承德ZPG120-10盘式真空过滤机顺利发货 ...

MORE